Introduction to Rigid-Flex PCB and Flexible PCB

In the world of electronics manufacturing, printed circuit boards (PCBs) play a crucial role in connecting and supporting various electronic components. As technology advances and devices become more compact and sophisticated, the demand for flexible and adaptable PCB solutions has grown significantly. Two notable types of PCBs that have gained popularity in recent years are Rigid-Flex PCBs and Flexible PCBs. While both offer unique advantages, it is essential to understand the differences between them to make informed decisions when designing and manufacturing electronic devices.

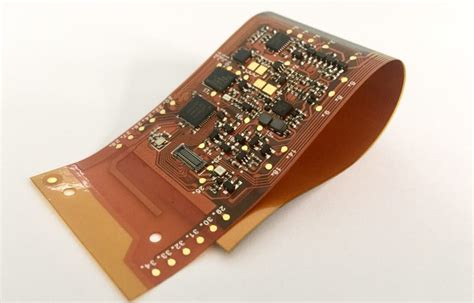

What is a Rigid-Flex PCB?

A Rigid-Flex PCB is a hybrid circuit board that combines the benefits of both rigid and flexible PCBs. It consists of multiple layers of flexible and rigid substrates laminated together, allowing for a more compact and reliable design. The rigid sections of the board provide structural support and stability, while the flexible sections allow for bending and folding, enabling the PCB to fit into tight spaces or conform to unique shapes.

Key Features of Rigid-Flex PCBs:

- Combination of rigid and flexible substrates

- Ability to bend and fold in specific areas

- Increased reliability and durability

- Reduced overall size and weight of the device

- Improved signal integrity and reduced electromagnetic interference (EMI)

What is a Flexible PCB?

A Flexible PCB, also known as a flex circuit or flex PCB, is a type of printed circuit board that is composed entirely of flexible materials. These boards are made using a thin, flexible substrate, such as polyimide or polyester, which allows them to bend and twist without damaging the electrical connections. Flexible PCBs are ideal for applications that require the board to fit into tight spaces, conform to unusual shapes, or withstand repeated flexing.

Key Features of Flexible PCBs:

- Thin and lightweight design

- High flexibility and ability to bend and twist

- Excellent resistance to vibration and shock

- Reduced assembly time and costs

- Suitable for applications with limited space or unique shapes

Advantages of Rigid-Flex PCBs

1. Enhanced Reliability and Durability

One of the primary advantages of Rigid-Flex PCBs is their enhanced reliability and durability compared to traditional PCBs. The combination of rigid and flexible substrates allows for a more robust design that can withstand the stresses of repeated bending and flexing. The rigid sections provide structural support and protection for the components, while the flexible sections allow for movement without compromising the electrical connections. This increased durability makes Rigid-Flex PCBs ideal for applications that require high reliability, such as aerospace, military, and medical devices.

2. Space Savings and Weight Reduction

Rigid-Flex PCBs offer significant space savings and weight reduction compared to traditional PCB designs. By combining multiple rigid boards and flexible interconnects into a single, compact package, designers can minimize the overall size and weight of the device. This is particularly beneficial in applications where space is limited, such as wearable technology, smartphones, and portable medical devices. The ability to fold and bend the PCB allows for more efficient use of available space, enabling designers to create smaller, lighter, and more compact products.

3. Improved Signal Integrity and Reduced EMI

Another advantage of Rigid-Flex PCBs is their ability to improve signal integrity and reduce electromagnetic interference (EMI). The flexible interconnects between the rigid sections allow for shorter signal paths, reducing the risk of signal degradation and cross-talk. Additionally, the close proximity of the layers in a Rigid-Flex PCB helps to minimize the loop area, which in turn reduces EMI. This is particularly important in high-frequency applications or devices that are sensitive to electromagnetic interference, such as medical equipment or communication systems.

4. Simplified Assembly and Reduced Costs

Rigid-Flex PCBs can simplify the assembly process and reduce overall manufacturing costs. By consolidating multiple rigid boards and flexible interconnects into a single PCB, the number of connectors and cables required is significantly reduced. This not only streamlines the assembly process but also minimizes the potential for errors and improves overall reliability. Furthermore, the reduced component count and simplified assembly can lead to lower manufacturing costs, making Rigid-Flex PCBs an attractive option for cost-sensitive applications.

Advantages of Flexible PCBs

1. High Flexibility and Conformity

Flexible PCBs offer unparalleled flexibility and conformity, making them ideal for applications that require the board to fit into tight spaces or conform to unusual shapes. The thin, flexible substrate allows the PCB to bend and twist without damaging the electrical connections, enabling designers to create products with unique form factors. This flexibility is particularly beneficial in wearable technology, where the PCB must conform to the contours of the human body, or in automotive applications, where the board must fit into tight spaces within the vehicle.

2. Lightweight and Thin Design

Another significant advantage of Flexible PCBs is their lightweight and thin design. The use of thin, flexible substrates, such as polyimide or polyester, allows for the creation of extremely thin and lightweight PCBs. This is particularly important in applications where weight and size are critical factors, such as aerospace, drones, and portable devices. The reduced weight and thickness of Flexible PCBs can also contribute to improved fuel efficiency and extended battery life in mobile devices.

3. Resistance to Vibration and Shock

Flexible PCBs exhibit excellent resistance to vibration and shock, making them suitable for applications that are subject to harsh environments or continuous movement. The flexible nature of the board allows it to absorb and dissipate the energy from vibrations and shocks, reducing the risk of damage to the electrical components. This is particularly important in automotive, aerospace, and industrial applications, where the PCB may be exposed to constant vibration or sudden impacts.

4. Reduced Assembly Time and Costs

Flexible PCBs can help to reduce assembly time and costs compared to traditional rigid PCBs. The flexibility of the board allows for easier routing and placement of components, simplifying the assembly process. Additionally, Flexible PCBs can be designed with fewer layers and a smaller footprint, reducing the overall material costs. The simplified assembly and reduced material requirements can lead to faster production times and lower manufacturing costs, making Flexible PCBs an attractive option for cost-sensitive applications.

Comparison Table: Rigid-Flex PCB vs. Flexible PCB

| Feature | Rigid-Flex PCB | Flexible PCB |

|---|---|---|

| Substrate | Combination of rigid and flexible substrates | Thin, flexible substrate (e.g., polyimide, polyester) |

| Flexibility | Bends and folds in specific areas | High flexibility, can bend and twist |

| Durability | High reliability and durability | Excellent resistance to vibration and shock |

| Size and Weight | Reduced size and weight compared to traditional PCBs | Lightweight and thin design |

| Signal Integrity | Improved signal integrity and reduced EMI | Suitable for high-speed applications |

| Assembly | Simplified assembly and reduced costs | Reduced assembly time and costs |

| Applications | Aerospace, military, medical devices, smartphones | Wearable technology, automotive, industrial |

Frequently Asked Questions (FAQ)

1. What are the main differences between Rigid-Flex PCBs and Flexible PCBs?

The main differences between Rigid-Flex PCBs and Flexible PCBs lie in their construction and flexibility. Rigid-Flex PCBs combine rigid and flexible substrates, allowing for bending and folding in specific areas while providing structural support. Flexible PCBs, on the other hand, are made entirely of flexible materials and offer high flexibility and conformity.

2. Which type of PCB is more durable, Rigid-Flex or Flexible?

Both Rigid-Flex PCBs and Flexible PCBs offer excellent durability, but in different ways. Rigid-Flex PCBs provide high reliability and durability due to the combination of rigid and flexible substrates, making them suitable for applications that require repeated bending and flexing. Flexible PCBs, on the other hand, exhibit excellent resistance to vibration and shock, making them ideal for harsh environments or continuous movement.

3. Are Rigid-Flex PCBs more expensive than Flexible PCBs?

In general, Rigid-Flex PCBs tend to be more expensive than Flexible PCBs due to their more complex manufacturing process and the combination of rigid and flexible substrates. However, the cost difference can vary depending on the specific design requirements, such as the number of layers, materials used, and the overall complexity of the PCB.

4. Which applications are best suited for Rigid-Flex PCBs?

Rigid-Flex PCBs are best suited for applications that require high reliability, durability, and compact designs. Some common applications include aerospace, military, medical devices, and smartphones. The ability to combine rigid and flexible sections allows for more efficient use of space and improved signal integrity, making Rigid-Flex PCBs a popular choice for these demanding applications.

5. Can Flexible PCBs be used in high-speed applications?

Yes, Flexible PCBs can be used in high-speed applications. The thin, flexible substrate and the ability to place components close together allow for shorter signal paths and reduced signal loss. However, proper design considerations, such as impedance control and shielding, must be taken into account to ensure optimal performance in high-speed applications.

Conclusion

Rigid-Flex PCBs and Flexible PCBs are two advanced types of printed circuit boards that offer unique advantages in terms of flexibility, durability, and performance. While Rigid-Flex PCBs provide a combination of structural support and flexibility, Flexible PCBs offer high conformity and resistance to vibration and shock. The choice between these two types of PCBs depends on the specific requirements of the application, such as space constraints, environmental factors, and performance needs.

As technology continues to evolve and the demand for compact, reliable, and flexible electronic devices grows, both Rigid-Flex PCBs and Flexible PCBs will play increasingly important roles in the electronics industry. By understanding the differences between these two types of PCBs and their respective advantages, designers and manufacturers can make informed decisions when developing the next generation of electronic products.

Leave a Reply