Introduction to Nelco and PCB Fabrication

Nelco is a leading manufacturer and fabricator of printed circuit boards (PCBs). With over 50 years of experience, Nelco has established itself as a trusted partner for businesses in various industries, providing high-quality PCBs for electronic devices and systems.

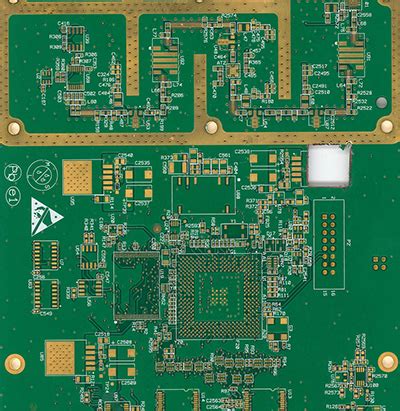

What are PCBs?

PCBs are the backbone of modern electronics. These flat boards are made of insulating materials, such as fiberglass or plastic, with conductive copper traces printed on them. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits, allowing them to function as a complete electronic system.

The Role of PCB Fabricators

PCB fabricators, like Nelco, play a crucial role in the electronics industry. They are responsible for manufacturing PCBs according to the designs and specifications provided by their clients. The fabrication process involves several steps, including:

- Printing the circuit design onto the copper-clad board

- Etching away the unwanted copper to create the desired circuit pattern

- Drilling holes for component placement

- Applying solder mask and silkscreen for protection and labeling

- Testing the finished PCB for functionality and quality

Nelco’s PCB Fabrication Capabilities

Nelco offers a wide range of PCB fabrication capabilities to meet the diverse needs of its clients. Some of the key features of Nelco’s PCB manufacturing services include:

Multi-layer PCBs

Nelco specializes in the fabrication of multi-layer PCBs, which consist of multiple layers of conductive circuits separated by insulating materials. These PCBs offer higher component density and improved signal integrity compared to single-layer boards. Nelco can manufacture PCBs with up to 30 layers, making them suitable for complex electronic systems.

High-Density Interconnect (HDI) PCBs

HDI PCBs feature finer traces and smaller vias, allowing for greater routing density and improved signal integrity. Nelco’s state-of-the-art manufacturing facilities are equipped to produce HDI PCBs with trace widths as narrow as 50 microns and via diameters as small as 0.1mm.

Flexible and Rigid-Flex PCBs

Nelco also offers fabrication services for flexible and rigid-flex PCBs. Flexible PCBs are made of thin, flexible materials that can bend and twist, making them ideal for applications where space is limited or where the PCB needs to conform to a specific shape. Rigid-flex PCBs combine the benefits of both rigid and flexible boards, allowing for greater design flexibility and improved reliability.

Material Options

Nelco works with a variety of PCB materials to suit different application requirements. Some of the common materials used in Nelco’s PCB fabrication include:

| Material | Characteristics | Typical Applications |

|---|---|---|

| FR-4 | Good electrical insulation, mechanical strength, and thermal stability | General-purpose electronics, industrial control systems, telecommunications equipment |

| Polyimide | High heat resistance, flexibility, and dimensional stability | Aerospace, military, and medical electronics |

| Rogers | Low dielectric loss, stable dielectric constant, and good thermal conductivity | High-frequency applications, such as RF and microwave circuits |

| Aluminum | Excellent thermal conductivity and heat dissipation properties | High-power electronics, LED lighting, and automotive applications |

Certifications and Quality Control

Nelco is committed to maintaining the highest standards of quality in its PCB fabrication processes. The company is ISO 9001:2015 certified, ensuring that its manufacturing processes adhere to strict quality management guidelines. Additionally, Nelco’s PCBs are RoHS compliant, meaning they are free from hazardous substances such as lead, mercury, and cadmium.

Nelco’s PCB Assembly Services

In addition to PCB fabrication, Nelco also offers PCB assembly services. PCB assembly involves soldering electronic components onto the fabricated PCB according to the design specifications. Nelco’s PCB assembly capabilities include:

Surface Mount Technology (SMT) Assembly

SMT assembly involves placing and soldering surface-mount components directly onto the PCB surface. This technology allows for higher component density and faster assembly compared to through-hole mounting. Nelco’s SMT assembly lines are equipped with state-of-the-art pick-and-place machines and reflow ovens, ensuring accurate and reliable component placement.

Through-Hole Assembly

Through-hole assembly involves inserting component leads through holes drilled in the PCB and soldering them on the opposite side. While this method is less common in modern electronics, it is still used for certain components, such as connectors and large capacitors. Nelco offers through-hole assembly services for clients who require this mounting technique.

Mixed Technology Assembly

Mixed technology assembly combines both SMT and through-hole mounting on a single PCB. This approach is often used when a design requires components that are not available in surface-mount packages or when certain components need to be mechanically secured to the board. Nelco’s assembly teams are skilled in handling mixed technology PCBs, ensuring a seamless integration of both mounting methods.

Automated Optical Inspection (AOI)

To ensure the quality and accuracy of its PCB assemblies, Nelco employs automated optical inspection (AOI) systems. AOI uses high-resolution cameras and advanced image processing algorithms to detect assembly defects, such as missing components, incorrect component placement, and solder bridging. This automated inspection process helps identify and correct issues early in the manufacturing process, reducing the risk of defective products reaching the customer.

Nelco’s Value-Added Services

Beyond PCB fabrication and assembly, Nelco offers a range of value-added services to support its clients throughout the product development lifecycle. These services include:

Design for Manufacturability (DFM) Review

Nelco’s experienced engineering team can review PCB designs to ensure they are optimized for manufacturability. This DFM review process helps identify potential issues, such as inadequate clearances, improper trace widths, and incompatible material selections, before the design enters production. By addressing these issues early, clients can avoid costly redesigns and production delays.

Prototyping and Quick-Turn Services

Nelco understands the importance of rapid prototyping in the product development process. The company offers quick-turn prototyping services, providing clients with functional PCB Prototypes within days of receiving the design files. This service allows clients to test and validate their designs quickly, accelerating the overall development timeline.

Testing and Validation

Nelco’s testing and validation services ensure that the fabricated PCBs and assembled boards meet the required performance and reliability standards. The company offers a range of testing services, including:

- In-circuit testing (ICT)

- Functional testing

- Boundary scan testing

- Environmental testing (temperature, humidity, and vibration)

By thoroughly testing the PCBs and assemblies, Nelco helps its clients identify and resolve any issues before the products are deployed in the field.

Nelco’s Industry Expertise

Nelco serves clients across various industries, each with its unique requirements and challenges. Some of the key industries Nelco caters to include:

Aerospace and Defense

Nelco has extensive experience in manufacturing PCBs for aerospace and defense applications. These applications demand the highest levels of reliability and performance, often in harsh environmental conditions. Nelco’s PCBs are designed and manufactured to withstand extreme temperatures, vibrations, and shock, ensuring reliable operation in mission-critical systems.

Medical Devices

The medical device industry requires PCBs that are both reliable and compliant with strict regulatory standards. Nelco’s manufacturing facilities are equipped to produce PCBs that meet the stringent requirements of medical device applications, such as implantable devices, diagnostic equipment, and patient monitoring systems. The company’s quality management system ensures that all PCBs are manufactured in accordance with the relevant medical device regulations.

Automotive Electronics

As vehicles become increasingly reliant on electronic systems, the demand for high-quality Automotive PCBs continues to grow. Nelco manufactures PCBs for a wide range of automotive applications, including engine control units, infotainment systems, and advanced driver assistance systems (ADAS). These PCBs are designed to withstand the harsh environmental conditions encountered in automotive environments, such as extreme temperatures, vibrations, and exposure to moisture and chemicals.

Industrial Automation and Control

Industrial automation and control systems require PCBs that are both reliable and capable of handling high power loads. Nelco’s PCBs are designed to meet the specific requirements of industrial applications, such as programmable logic controllers (PLCs), motor drives, and power distribution systems. The company’s expertise in thermal management and high-current design ensures that its PCBs can operate reliably in demanding industrial environments.

Frequently Asked Questions (FAQ)

1. What is the minimum order quantity for PCBs at Nelco?

Nelco offers flexible minimum order quantities (MOQs) depending on the specific requirements of the project. For standard PCBs, the MOQ can be as low as 5 pieces. However, for more complex designs or specialty materials, the MOQ may be higher. It is best to contact Nelco’s sales team to discuss your specific project requirements and determine the applicable MOQ.

2. How long does it take to manufacture PCBs at Nelco?

The lead time for PCB manufacturing at Nelco depends on various factors, such as the complexity of the design, the number of layers, and the selected materials. For standard PCBs, lead times can range from 5 to 15 working days. Rush services are available for time-sensitive projects, with lead times as short as 24 hours for simple designs. Nelco’s sales team can provide a more accurate lead time estimate based on your specific project requirements.

3. What file formats does Nelco accept for PCB design submissions?

Nelco accepts PCB design files in various industry-standard formats, including Gerber RS-274X, ODB++, and IPC-2581. The company also accepts design files from popular PCB design software, such as Altium Designer, Cadence Allegro, and Mentor Graphics PADS. When submitting design files, it is important to include all the necessary layers, such as copper, solder mask, and silkscreen, along with the drill files and any additional fabrication notes.

4. Does Nelco offer PCB design services?

While Nelco primarily focuses on PCB fabrication and assembly, the company does offer limited PCB design services. These services are typically aimed at helping clients optimize their existing designs for manufacturability, rather than creating designs from scratch. If you require comprehensive PCB design services, Nelco can recommend trusted design partners who specialize in this area.

5. What certifications and quality standards does Nelco adhere to?

Nelco is committed to maintaining the highest standards of quality in its PCB fabrication and assembly processes. The company is ISO 9001:2015 certified, which demonstrates its adherence to strict quality management guidelines. Additionally, Nelco’s PCBs are manufactured in accordance with IPC-A-600 and IPC-6012 standards, ensuring consistent quality and reliability. The company’s PCBs are also RoHS compliant, meeting the requirements for the restriction of hazardous substances in electronic products.

Conclusion

Nelco is a leading PCB manufacturer and fabricator, offering a comprehensive range of services to clients across various industries. With its state-of-the-art manufacturing facilities, experienced engineering team, and commitment to quality, Nelco is well-positioned to meet the evolving needs of the electronics industry.

From multi-layer and HDI PCBs to flexible and rigid-flex designs, Nelco’s PCB fabrication capabilities are designed to support a wide range of applications. The company’s PCB assembly services, including SMT, through-hole, and mixed technology assembly, provide clients with a one-stop solution for their electronic manufacturing needs.

Nelco’s value-added services, such as DFM review, prototyping, and testing, help clients streamline their product development processes and ensure the highest levels of quality and reliability. With its expertise in serving industries such as aerospace, defense, medical devices, automotive electronics, and industrial automation, Nelco is a trusted partner for businesses seeking high-quality PCBs and electronic manufacturing services.

As the electronics industry continues to evolve, Nelco remains committed to investing in the latest technologies and processes to meet the changing needs of its clients. With its focus on quality, reliability, and customer service, Nelco is well-positioned to support the growth and success of its clients in the years to come.

Leave a Reply