Introduction

When it comes to introducing a new product, having a reliable and efficient PCB Prototype service is crucial. The printed circuit board (PCB) is the backbone of any electronic device, and the quality of the PCB prototype can make or break your product’s success. In this article, we will discuss the key factors to consider when choosing a PCB prototype service for your new product introduction (NPI).

What is a PCB Prototype?

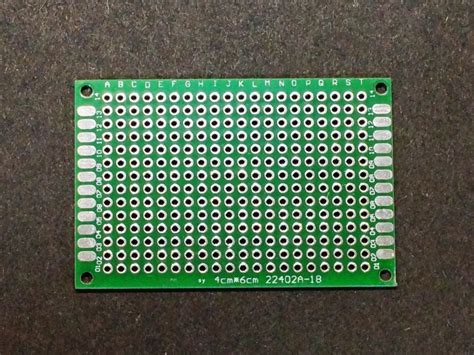

A PCB prototype is a preliminary version of a printed circuit board that is used for testing and validation purposes before mass production. It allows engineers and designers to verify the functionality, performance, and compatibility of the circuit design with other components. PCB Prototypes are essential for identifying and resolving any issues early in the development process, saving time and money in the long run.

Why is Choosing the Right PCB Prototype Service Important?

Selecting the right PCB prototype service is critical for several reasons:

-

Quality: A high-quality PCB prototype ensures that your final product will function as intended. Poor quality prototypes can lead to delays, additional costs, and even product failures.

-

Time-to-Market: Choosing a PCB prototype service that can deliver your prototypes quickly allows you to speed up your development process and bring your product to market faster.

-

Cost: Working with a cost-effective PCB prototype service helps you manage your budget and allocate resources efficiently.

-

Expertise: Partnering with a PCB prototype service that has experience in your industry and can provide valuable insights and recommendations can enhance your product’s overall design and performance.

Factors to Consider When Choosing a PCB Prototype Service

1. Technical Capabilities

When evaluating a PCB prototype service, consider their technical capabilities:

-

Manufacturing Technology: Ensure that the service provider has the necessary equipment and expertise to handle your specific PCB requirements, such as multi-layer boards, high-density interconnects (HDI), or flexible PCBs.

-

Design Support: Look for a service that offers design assistance, such as design for manufacturability (DFM) analysis, to help optimize your PCB design for production.

-

Material Selection: Check if the service has experience working with the materials you require, such as FR4, high-frequency laminates, or metal-core PCBs.

2. Quality Control and Certifications

Quality control is essential for ensuring the reliability and performance of your PCB prototypes. When choosing a PCB prototype service, consider the following:

-

Quality Management System: Look for a service provider with a robust quality management system, such as ISO 9001 certification, to ensure consistent quality and continuous improvement.

-

Testing and Inspection: Inquire about the service’s testing and inspection processes, including automated optical inspection (AOI), X-ray inspection, and electrical testing.

-

Industry Standards: Ensure that the service complies with relevant industry standards, such as IPC (Association Connecting Electronics Industries) or UL (Underwriters Laboratories), depending on your product’s requirements.

3. Turnaround Time and Flexibility

The speed at which a PCB prototype service can deliver your prototypes is crucial for meeting your NPI timeline. Consider the following factors:

-

Standard Turnaround Time: Check the service’s standard turnaround time for PCB prototypes and whether it aligns with your project schedule.

-

Expedited Options: Inquire about expedited services for urgent projects and the associated costs.

-

Flexibility: Look for a service that can accommodate changes or revisions to your design without significant delays or additional costs.

4. Cost and Pricing Structure

Cost is an important factor when choosing a PCB prototype service, but it should not be the sole deciding factor. Consider the following:

-

Pricing Transparency: Look for a service that provides clear and transparent pricing, including any additional fees for expedited services, design support, or shipping.

-

Volume Discounts: If you anticipate needing multiple prototypes or larger quantities, inquire about volume discounts.

-

Value for Money: Evaluate the overall value provided by the service, considering factors such as quality, turnaround time, and support, rather than just the lowest price.

5. Customer Support and Communication

Effective communication and customer support are essential for a smooth NPI process. Consider the following:

-

Responsiveness: Look for a service that is responsive to your inquiries and provides timely updates on your project’s status.

-

Technical Support: Ensure that the service offers technical support to help you resolve any issues or answer questions about your PCB prototype.

-

Language and Time Zone: If you are working with a global PCB prototype service, consider their language capabilities and time zone differences to ensure effective communication.

PCB Prototype Service Comparison

To help you compare different PCB Prototype Services, we have created a table with some key factors to consider:

| Service Provider | Technical Capabilities | Certifications | Turnaround Time | Pricing |

|---|---|---|---|---|

| Service A | Multi-layer, HDI | ISO 9001, IPC | 5-7 days | $$$ |

| Service B | Standard, Flexible | ISO 9001 | 10-12 days | $$ |

| Service C | Multi-layer, HDI, Flex | ISO 9001, UL | 3-5 days | $$$$ |

Note: Pricing is indicated by $ symbols, with more symbols representing higher relative costs.

Frequently Asked Questions (FAQ)

- What is the minimum order quantity (MOQ) for PCB prototypes?

-

MOQs vary between service providers, but many offer low or even no MOQ for prototypes. Check with your chosen service for their specific requirements.

-

How long does it typically take to receive PCB prototypes?

-

Standard turnaround times range from 3 to 12 days, depending on the complexity of your design and the service provider you choose. Expedited options may be available for faster delivery.

-

Can I get assistance with my PCB design?

-

Many PCB prototype services offer design support, such as DFM analysis and design recommendations. Inquire with your chosen service about their design support options.

-

What file formats are required for PCB prototype ordering?

-

Most PCB prototype services accept standard file formats such as Gerber, ODB++, and IPC-2581. Some services may also accept CAD files from popular PCB design software.

-

How can I ensure the quality of my PCB prototypes?

- Choose a PCB prototype service with a strong quality management system, relevant certifications, and a reputation for delivering high-quality prototypes. Communicate your quality requirements clearly and request testing and inspection reports.

Conclusion

Choosing the right PCB prototype service is essential for the success of your new product introduction. Consider factors such as technical capabilities, quality control, turnaround time, cost, and customer support when evaluating potential service providers. By partnering with a reliable and experienced PCB prototype service, you can ensure that your product development process runs smoothly and efficiently, ultimately leading to a successful product launch.

Leave a Reply