Introduction to PCB Prototypes

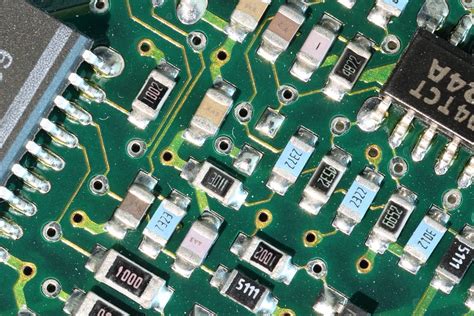

Printed Circuit Board (PCB) prototypes are essential for testing and validating electronic designs before moving into full-scale production. PCB Prototyping allows designers and engineers to physically realize their circuits, test functionality, and identify any issues or improvements needed.

In this article, we will explore low-cost options for creating 1 to 4 layer PCB prototypes. We’ll cover the PCB design process, prototyping methods, and key considerations to help you get started with affordable, high-quality PCB prototypes.

The Importance of PCB Prototyping

Validating Designs

One of the primary reasons for creating PCB prototypes is to validate the design and ensure it functions as intended. Prototypes allow you to:

- Test the circuit’s performance

- Verify component placement and routing

- Identify any design flaws or errors

- Make necessary revisions before mass production

By validating your design through prototyping, you can save time and money by catching issues early in the development process.

Proof of Concept

PCB prototypes serve as a proof of concept, demonstrating that your design is feasible and meets the required specifications. A working prototype can be used to:

- Showcase your product to potential investors or customers

- Gather feedback and make improvements based on user testing

- Provide a tangible representation of your idea

Having a functional PCB prototype increases confidence in your design and helps secure support for further development.

Cost Savings

Creating PCB prototypes can actually lead to cost savings in the long run. By identifying and resolving issues during the prototyping stage, you can avoid costly mistakes and redesigns later in the production process. Prototyping allows you to:

- Optimize your design for manufacturability

- Test different materials and components

- Refine your bill of materials (BOM)

- Get quotes from multiple PCB manufacturers

Investing in thorough prototyping can ultimately reduce overall project costs and lead to a more successful final product.

PCB Design Process

Before diving into PCB prototyping, it’s essential to understand the PCB design process. The following steps outline the typical workflow for creating a PCB:

Schematic Design

The first step is to create a schematic diagram of your circuit. This involves:

- Selecting components and defining their values

- Creating the electrical connections between components

- Assigning reference designators to each component

Various PCB design software tools, such as KiCad, Eagle, or Altium Designer, can be used to create schematic diagrams.

Component Placement

Once the schematic is complete, the next step is to place the components on the PCB layout. Consider the following factors when placing components:

- Functionality: Group related components together for optimal performance

- Size: Ensure components fit within the available board space

- Orientation: Follow component datasheets for proper orientation

- Accessibility: Place components for easy soldering and maintenance

Proper component placement is crucial for a successful PCB design.

Routing

After placing the components, you need to route the electrical connections between them. Routing involves creating copper traces on the PCB layers to establish the desired connectivity. Consider the following when routing your PCB:

- Signal integrity: Ensure traces are properly sized and spaced to minimize interference

- Power distribution: Provide adequate power and ground connections to all components

- Manufacturability: Follow PCB manufacturer guidelines for trace width, spacing, and via sizing

- Electromagnetic compatibility (EMC): Implement techniques to minimize electromagnetic interference

Efficient routing is essential for a reliable and manufacturable PCB.

Design Rule Check (DRC)

Before finalizing your PCB layout, perform a design rule check (DRC) to ensure your design meets the manufacturing requirements. DRC helps identify issues such as:

- Minimum trace width and spacing violations

- Insufficient clearance between components

- Missing or overlapping connections

- Unconnected pins or nets

Resolving DRC errors ensures your PCB can be manufactured without issues.

Gerber File Generation

Once your PCB layout is complete and has passed DRC, generate the Gerber files required for manufacturing. Gerber files are industry-standard file formats that contain the necessary information for PCB fabrication, including:

- Copper layers

- Solder mask layers

- Silkscreen layers

- Drill files

Most PCB design software tools have built-in Gerber file generation capabilities.

PCB Prototyping Methods

There are several methods for creating PCB prototypes, each with its own advantages and considerations. Let’s explore some common PCB prototyping methods:

In-House Prototyping

In-house PCB prototyping involves creating the prototype within your own facility or workspace. This method offers the most control over the process and allows for quick iterations. In-house prototyping options include:

- PCB milling: Using a CNC machine to mill away unwanted copper from a pre-coated board

- PCB Etching: Chemically removing unwanted copper using a photoresist and etchant solution

- PCB printing: Using a desktop PCB printer to directly print conductive traces onto a substrate

In-house prototyping requires an initial investment in equipment and materials but can be cost-effective for frequent prototyping needs.

Outsourcing to PCB Manufacturers

Outsourcing your PCB prototypes to professional PCB manufacturers is a popular choice, especially for complex designs or higher quantities. Benefits of outsourcing include:

- Access to advanced manufacturing capabilities and materials

- Higher quality and reliability compared to in-house methods

- Faster turnaround times for larger quantities

- No need for in-house equipment or expertise

When outsourcing, research and compare different PCB manufacturers to find the best fit for your project requirements and budget.

PCB Assembly (PCBA)

PCB assembly (PCBA) involves soldering components onto the fabricated PCB. PCBA options for prototypes include:

- Hand soldering: Manually soldering components using a soldering iron

- Reflow soldering: Using a reflow oven to solder surface mount components

- Wave soldering: Passing the PCB over a wave of molten solder to solder through-hole components

Consider your component types, quantities, and available resources when choosing a PCBA method for your prototypes.

Low-Cost PCB Prototyping Tips

To minimize costs while still achieving high-quality PCB prototypes, consider the following tips:

1. Keep the Layer Count Low

Stick to 1 or 2 layer PCBs whenever possible, as they are less expensive than multi-layer boards. If your design requires more than 2 layers, consider a 4-layer board as a cost-effective option compared to higher layer counts.

2. Use Standard Materials

Choose standard PCB materials, such as FR-4, to keep costs down. Specialized materials like high-frequency laminates or metal-core PCBs are more expensive and may not be necessary for most prototyping purposes.

3. Opt for Larger Minimum Feature Sizes

Specify larger minimum trace widths, spacings, and via sizes to reduce manufacturing costs. Smaller feature sizes require more advanced manufacturing processes, which can increase prototype costs.

4. Minimize the PCB Dimensions

Design your PCB to be as compact as possible while still accommodating all necessary components. Smaller PCB dimensions reduce material costs and can potentially lower manufacturing fees.

5. Choose Cost-Effective Components

Select components that offer the best value for your design. Consider factors such as package type, availability, and price when making component choices.

6. Use Online PCB Prototyping Services

There are many online PCB prototyping services that offer competitive pricing and fast turnaround times. These services often have user-friendly interfaces and provide instant quotes based on your design specifications.

Some popular online PCB prototyping services include:

| Service | Layers | Lead Time | Price (1-4 Layer, 5pcs) |

|---|---|---|---|

| JLCPCB | 1-6 | 24 hours | $2 – $30 |

| PCBWay | 1-6 | 24 hours | $5 – $50 |

| OSH Park | 1-6 | 5-12 days | $5 – $120 |

*Prices and lead times are approximate and subject to change.

By leveraging online services, you can access affordable PCB prototyping without the need for in-house equipment or expertise.

Frequently Asked Questions (FAQ)

1. What is the typical turnaround time for PCB prototypes?

The turnaround time for PCB prototypes varies depending on the complexity of the design, the prototyping method, and the manufacturer. In-house prototyping can often be completed within a day or two, while outsourcing to a PCB manufacturer typically takes 1-2 weeks, depending on the service level chosen.

2. How much do PCB prototypes typically cost?

The cost of PCB prototypes depends on factors such as the number of layers, board dimensions, quantity, and additional services like assembly or special finishes. For 1-4 layer PCBs, prototype costs can range from a few dollars to a few hundred dollars, depending on the specific requirements.

3. What file formats are required for PCB prototyping?

The most common file format for PCB prototyping is the Gerber file format. Gerber files contain the necessary information for PCB fabrication, including the copper layers, solder mask, silkscreen, and drill data. Most PCB manufacturers also accept other file formats, such as ODB++, DXF, or IPC-2581.

4. Can I get assembled PCB prototypes?

Yes, many PCB prototyping services offer assembly options. You can provide the bill of materials (BOM) and component placement files, and the manufacturer will source the components and assemble the PCBs for you. This can save time and effort compared to hand soldering the prototypes yourself.

5. How can I ensure the quality of my PCB prototypes?

To ensure the quality of your PCB prototypes:

- Follow good PCB design practices and guidelines

- Perform thorough design rule checks (DRC) before manufacturing

- Choose reputable PCB prototyping services with proven track records

- Specify appropriate quality control measures, such as electrical testing or visual inspection

- Provide clear and accurate documentation, including Gerber files, BOM, and assembly instructions

By following these practices, you can minimize the risk of manufacturing issues and ensure high-quality PCB prototypes.

Conclusion

Creating low-cost 1 to 4 layer PCB prototypes is an essential step in the electronic design process. By understanding the PCB design workflow, exploring different prototyping methods, and implementing cost-saving tips, you can achieve affordable and high-quality prototypes for your projects. Whether you choose in-house prototyping or outsource to a PCB manufacturer, careful planning and attention to detail will help you succeed in your PCB prototyping endeavors.

Leave a Reply