Introduction to PCB Fabricators

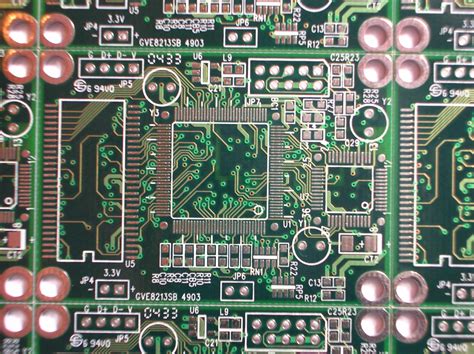

Printed Circuit Board (PCB) fabricators play a crucial role in the electronics industry by manufacturing Prototype PCBs for various applications. These manufacturers specialize in creating custom-designed circuit boards that meet the specific requirements of their clients. Prototype PCB fabrication is an essential step in the product development process, allowing designers and engineers to test and refine their designs before mass production.

What is a Prototype PCB?

A prototype PCB is a preliminary version of a printed circuit board that is used for testing and evaluation purposes. It is designed to verify the functionality, performance, and compatibility of the circuit design before proceeding with full-scale production. Prototype PCBs are typically manufactured in small quantities and may undergo several iterations based on the feedback and results obtained during the testing phase.

Importance of Prototype PCB Fabrication

Prototype PCB fabrication is a critical step in the product development lifecycle for several reasons:

-

Design Validation: Prototype PCBs allow designers to validate their circuit designs and ensure that they function as intended. Any design flaws or issues can be identified and rectified at this stage, saving time and resources in the long run.

-

Functionality Testing: By fabricating prototype PCBs, engineers can perform thorough testing and evaluation of the circuit’s functionality. This includes testing the board’s performance under various operating conditions, such as temperature, humidity, and electrical stress.

-

Compatibility Assessment: Prototype PCBs enable designers to assess the compatibility of the circuit board with other components and systems. This is particularly important when integrating the PCB into a larger electronic assembly or device.

-

Cost Savings: Identifying and resolving design issues during the prototype stage can significantly reduce the overall cost of product development. It is much more cost-effective to make changes and iterations on prototype PCBs rather than discovering problems during mass production.

Choosing the Right PCB Fabricator

Selecting the right PCB fabricator is essential to ensure the success of your prototype PCB project. Here are some key factors to consider when choosing a PCB fabricator:

Technical Capabilities

Evaluate the technical capabilities of the PCB fabricator to ensure they can meet your specific requirements. Consider factors such as:

- PCB material options (FR-4, high-frequency laminates, flexible substrates, etc.)

- Number of layers supported

- Minimum feature sizes (trace width, spacing, hole size)

- Surface finishes available (HASL, ENIG, OSP, etc.)

- Impedance control and controlled impedance capabilities

- Blind and buried via capabilities

Manufacturing Processes and Quality Control

Assess the manufacturing processes and quality control measures employed by the PCB fabricator. Look for fabricators that adhere to industry standards and have a robust quality management system in place. Some key considerations include:

- IPC standards compliance (IPC-A-600, IPC-6012, etc.)

- ISO certifications (ISO 9001, ISO 14001, etc.)

- Automated inspection systems (AOI, X-ray, etc.)

- Electrical testing capabilities (flying probe, ICT, etc.)

- Traceability and documentation practices

Turnaround Time and Pricing

Consider the turnaround time and pricing offered by the PCB fabricator. Prototype PCB projects often have tight deadlines, so it’s crucial to choose a fabricator that can deliver high-quality boards within the required timeframe. Additionally, compare pricing from multiple fabricators to ensure you are getting a competitive rate without compromising on quality.

Customer Support and Communication

Effective communication and responsive customer support are essential when working with a PCB fabricator. Look for fabricators that provide clear communication channels, such as dedicated account managers or online portals, to streamline the ordering and tracking process. Prompt and knowledgeable technical support can also be invaluable in resolving any issues or questions that may arise during the prototype PCB fabrication process.

Top Prototype PCB Fabricators

Here are some of the top prototype PCB fabricators known for their expertise and quality:

| Fabricator | Specialization | Turnaround Time | Minimum Quantity |

|---|---|---|---|

| Advanced Circuits | Quick-turn prototypes, HDI, flex PCBs | 1-5 days | 1 |

| PCBWay | Low-cost prototypes, standard and advanced PCBs | 1-3 days | 5 |

| Sierra Circuits | High-complexity PCBs, HDI, RF/microwave | 2-10 days | 1 |

| Sunstone Circuits | Quick-turn prototypes, standard and advanced PCBs | 1-5 days | 1 |

| OSH Park | Low-cost prototypes, community-driven platform | 5-12 days | 3 |

Note: The information provided in the table is based on typical offerings and may vary depending on specific requirements and project complexity.

These fabricators offer a range of services and specializations to cater to different prototype PCB needs. It’s essential to review their capabilities and engage with them to determine the best fit for your specific project.

Preparing Files for Prototype PCB Fabrication

To ensure a smooth and successful prototype PCB fabrication process, it’s crucial to prepare your design files properly. Here are some guidelines to follow:

Gerber Files

Gerber files are the industry standard for PCB fabrication. They contain the necessary information for each layer of the PCB, including copper traces, solder mask, silkscreen, and drill data. When generating Gerber files, consider the following:

- Use a reliable PCB design software that can export high-quality Gerber files.

- Ensure that all layers are included and properly named according to the fabricator’s specifications.

- Specify the correct aperture sizes and types for each layer.

- Include a readme file or fabrication notes to provide any additional instructions or requirements.

Drill Files

Drill files contain the information for the holes and vias on the PCB. They specify the size and location of each hole. When preparing drill files, keep these points in mind:

- Generate separate drill files for through-holes and blind/buried vias, if applicable.

- Use standard drill sizes and avoid unnecessary hole sizes to minimize tooling costs.

- Specify the correct drill file format (Excellon, ASCII, etc.) as per the fabricator’s requirements.

Board Outline and Panelization

The board outline defines the physical shape and size of the PCB. If you require multiple copies of your prototype PCB, consider panelization to optimize manufacturing efficiency. Follow these guidelines:

- Include a clear board outline layer in your design files.

- Ensure that the board outline follows the fabricator’s minimum spacing and clearance requirements.

- If panelizing, provide clear instructions on the panel layout, including the number of boards, spacing between boards, and any special requirements.

File Formats and Compression

When sending your design files to the PCB fabricator, ensure that you use the appropriate file formats and compression methods. Most fabricators accept the following:

- Gerber files: RS-274X format

- Drill files: Excellon format

- CAD files: ODB++, IPC-2581, or native CAD formats (e.g., Altium, KiCad, Eagle)

- Compression: ZIP or RAR format

Always double-check the fabricator’s specific file submission requirements to avoid any delays or issues.

Prototype PCB Assembly (PCBA)

In addition to PCB fabrication, many prototype PCB manufacturers also offer assembly services. Prototype PCB assembly (PCBA) involves soldering components onto the fabricated PCB to create a functional electronic assembly. Here are some considerations for prototype PCBA:

Bill of Materials (BOM)

Provide a comprehensive bill of materials (BOM) that lists all the components required for the assembly. The BOM should include the following information:

- Component reference designators

- Manufacturer part numbers

- Quantities

- Description and package type

- Any special handling or sourcing instructions

Component Sourcing

Determine whether you will provide the components for assembly or rely on the PCBA provider to source them. If you are providing the components, ensure that they are properly packaged, labeled, and shipped to the assembly facility. If the PCBA provider is sourcing the components, provide clear instructions on the preferred suppliers and any specific requirements.

Assembly Instructions

Provide detailed assembly instructions to guide the PCBA process. This may include:

- Assembly drawings or CAD files showing component placement

- Soldering specifications (e.g., lead-free, RoHS compliant)

- Any special handling or assembly requirements

- Testing and inspection criteria

- Packaging and shipping instructions

Prototype PCBA Providers

Many prototype PCB fabricators also offer PCBA services, providing a one-stop solution for your prototype needs. Some notable providers include:

- Advanced Circuits

- PCBWay

- Sierra Circuits

- Sunstone Circuits

When choosing a prototype PCBA provider, consider their experience, capabilities, turnaround time, and pricing. Effective communication and close collaboration with the provider are essential to ensure successful prototype PCBA outcomes.

Frequently Asked Questions (FAQ)

-

What is the typical turnaround time for prototype PCB fabrication?

The turnaround time for prototype PCB fabrication varies depending on the complexity of the design and the fabricator’s capabilities. Most prototype PCB fabricators offer standard turnaround times ranging from 1 to 5 days for simple designs. However, more complex designs or specialized requirements may take longer, typically 7 to 14 days. -

How much does prototype PCB fabrication cost?

The cost of prototype PCB fabrication depends on several factors, including the PCB size, number of layers, complexity, materials, surface finish, and quantity. Prototype quantities usually range from 1 to 100 pieces. For a basic 2-layer PCB, the cost can range from $30 to $100 for a small quantity. As the complexity and quantity increase, the cost per unit typically decreases. It’s best to obtain quotes from multiple fabricators based on your specific requirements. -

What are the minimum feature sizes for prototype PCBs?

The minimum feature sizes for prototype PCBs vary depending on the fabricator’s capabilities. Typical minimum feature sizes include: - Trace width/spacing: 3-4 mil (0.075-0.1 mm)

- Hole size: 8 mil (0.2 mm)

-

Clearance: 3-4 mil (0.075-0.1 mm)

However, some advanced fabricators can accommodate smaller feature sizes, such as 2 mil traces and 6 mil holes, for high-density designs. -

Can I get assembled prototype PCBs (PCBA)?

Yes, many prototype PCB fabricators offer assembly services (PCBA) in addition to PCB fabrication. They can source components, solder them onto the fabricated PCBs, and perform basic testing and inspection. This can be a convenient option for getting fully assembled prototype boards. However, it’s essential to provide a complete and accurate bill of materials (BOM) and assembly instructions to ensure successful PCBA. -

What files do I need to submit for prototype PCB fabrication?

To fabricate your prototype PCBs, you typically need to submit the following files: - Gerber files: These include the copper layers, solder mask, silkscreen, and other necessary layers.

- Drill files: These specify the location and size of holes and vias on the PCB.

- Board outline: This defines the physical shape and size of the PCB.

- Fabrication notes: Any additional instructions or requirements for the fabricator.

Most fabricators accept Gerber files in RS-274X format and drill files in Excellon format. Some may also accept CAD files in ODB++, IPC-2581, or native CAD formats.

Conclusion

Prototype PCB fabrication is a critical step in the product development process, enabling designers and engineers to validate their designs, test functionality, and optimize performance before moving to mass production. Choosing the right PCB fabricator is essential to ensure high-quality prototype boards that meet your specific requirements.

When selecting a prototype PCB fabricator, consider their technical capabilities, manufacturing processes, quality control measures, turnaround time, pricing, and customer support. Effective communication and collaboration with the fabricator are key to achieving successful prototype PCB outcomes.

By following best practices for preparing design files, providing clear instructions, and leveraging the expertise of reliable prototype PCB fabricators, you can streamline your product development process and bring your electronic designs to life efficiently and cost-effectively.

Leave a Reply