Introduction to PCB Assembly and BGA Technology

Printed Circuit Board (PCB) assembly is a crucial process in the electronics manufacturing industry. It involves the placement and soldering of various electronic components onto a PCB to create a functional electronic device. One of the most important components in modern PCB assembly is the Ball Grid Array (BGA) package.

BGA packages are surface-mount devices that use an array of solder balls to connect the integrated circuit (IC) to the PCB. This technology offers several advantages over traditional packaging methods, such as:

- Increased packaging density

- Improved electrical performance

- Better thermal dissipation

- Reduced lead inductance

The Importance of Choosing the Right BGA PCB Assembly Company

Selecting a reliable and experienced BGA PCB assembly company is essential for ensuring the quality and reliability of your electronic products. A competent assembly partner should have:

- State-of-the-art equipment and facilities

- Skilled technicians and engineers

- Stringent quality control processes

- Experience with a wide range of BGA package types and sizes

- Ability to handle high-volume production runs

Top BGA PCB Assembly Companies

To help you find the best BGA PCB assembly partner for your project, we have compiled a list of some of the top companies in the industry.

1. Foxconn

Foxconn is a Taiwanese electronics manufacturing giant known for its partnerships with major technology companies like Apple, Dell, and Sony. The company has extensive experience in BGA PCB assembly and offers a wide range of services, including:

- Design for Manufacturing (DFM) support

- Prototype and small-batch production

- High-volume manufacturing

- Testing and quality assurance

| Facility Locations | Key Clients | Certifications |

|---|---|---|

| China, Taiwan, USA, Mexico, Brazil, Europe | Apple, Dell, HP, Sony | ISO 9001, ISO 14001, IATF 16949, ISO 13485 |

2. Jabil

Jabil is a global manufacturing services company with a strong presence in the BGA PCB assembly market. The company offers a comprehensive range of services, from design and engineering to manufacturing and supply chain management. Some of Jabil’s key features include:

- Advanced BGA Assembly capabilities

- In-house design and engineering teams

- Global footprint with facilities in over 30 countries

- Expertise in various industries, including automotive, healthcare, and telecommunications

| Facility Locations | Key Clients | Certifications |

|---|---|---|

| Americas, Europe, Asia | Cisco, HP, IBM, Philips | ISO 9001, ISO 13485, ISO 14001, IATF 16949 |

3. Flextronics (Flex)

Flextronics, now known as Flex, is a Singapore-based electronics manufacturing services company with a strong focus on BGA PCB assembly. The company provides end-to-end solutions for a wide range of industries, including:

- Consumer electronics

- Automotive

- Healthcare

- Industrial

Flex’s BGA assembly capabilities include:

- Fine-pitch BGA placement

- Package-on-Package (PoP) assembly

- 3D packaging

- Advanced testing and inspection

| Facility Locations | Key Clients | Certifications |

|---|---|---|

| Americas, Europe, Asia | Cisco, Dell, HP, Lenovo | ISO 9001, ISO 13485, ISO 14001, IATF 16949 |

4. Celestica

Celestica is a Canadian electronics manufacturing services company with a significant presence in the BGA PCB assembly market. The company offers a wide range of services, including:

- Design and engineering support

- Prototype and low-volume production

- High-volume manufacturing

- Supply chain management

Celestica’s BGA assembly capabilities include:

- Multiple BGA package types and sizes

- Advanced process control and monitoring

- Automated optical inspection (AOI) and X-ray inspection

- Functional testing and burn-in

| Facility Locations | Key Clients | Certifications |

|---|---|---|

| Americas, Europe, Asia | Cisco, Dell, IBM, Juniper Networks | ISO 9001, ISO 13485, ISO 14001, IATF 16949 |

5. Sanmina

Sanmina is a US-based electronics manufacturing services company with a strong focus on BGA PCB assembly. The company serves a wide range of industries, including:

- Medical

- Automotive

- Communications

- Defense and aerospace

Sanmina’s BGA assembly capabilities include:

- High-density BGA placement

- Package-on-Package (PoP) assembly

- 3D packaging

- Advanced testing and inspection

| Facility Locations | Key Clients | Certifications |

|---|---|---|

| Americas, Europe, Asia | Cisco, Dell, HP, Lenovo | ISO 9001, ISO 13485, ISO 14001, IATF 16949 |

Factors to Consider When Choosing a BGA PCB Assembly Company

When selecting a BGA PCB assembly partner, there are several key factors to consider to ensure a successful collaboration.

1. Technical Capabilities

Assess the company’s technical capabilities, including:

- Experience with different BGA package types and sizes

- State-of-the-art equipment and facilities

- Skilled technicians and engineers

- Quality control processes and certifications

2. Industry Experience

Consider the company’s experience in your specific industry, as well as their understanding of industry-specific regulations and standards.

3. Scalability

Evaluate the company’s ability to scale production to meet your current and future needs, from prototype and low-volume production to high-volume manufacturing.

4. Design and Engineering Support

Look for a company that offers design and engineering support to help optimize your PCB design for manufacturability and reliability.

5. Supply Chain Management

Choose a company with a robust supply chain management system to ensure the timely delivery of components and finished products.

6. Communication and Collaboration

Select a company that values open communication and collaboration, with a dedicated project manager to oversee your project and provide regular updates.

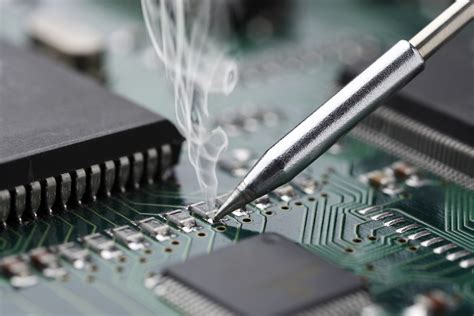

The BGA PCB Assembly Process

The BGA PCB assembly process typically involves the following steps:

-

Solder Paste Printing: Solder paste is applied to the PCB pads using a stencil or screen printing process.

-

Component Placement: BGA components are placed onto the PCB using a pick-and-place machine, which accurately positions the components based on the PCB design.

-

Reflow Soldering: The PCB is heated in a reflow oven, causing the solder paste to melt and form a strong bond between the BGA component and the PCB pads.

-

Inspection: The assembled PCB undergoes visual and automated optical inspection (AOI) to detect any defects or irregularities.

-

Testing: Functional testing is performed to ensure that the assembled PCB meets the required specifications and performance criteria.

Challenges in BGA PCB Assembly

BGA PCB assembly presents several challenges that must be addressed to ensure reliable and high-quality results.

1. Thermal Management

BGA packages generate a significant amount of heat, which must be effectively dissipated to prevent thermal stress and ensure reliable performance. Proper PCB design and the use of thermal management techniques, such as heat sinks and thermal vias, are essential.

2. Warpage and Coplanarity

BGA packages are susceptible to warpage and coplanarity issues, which can lead to poor solder joint formation and reliability problems. Careful component selection, PCB design, and process control are necessary to minimize these issues.

3. Solder Joint Reliability

The reliability of BGA solder joints is critical to the overall performance and longevity of the electronic device. Factors such as solder paste selection, reflow profile optimization, and proper handling and storage of components can significantly impact solder joint reliability.

4. Rework and Repair

Reworking and repairing BGA assemblies can be challenging due to the high density of solder balls and the difficulty in accessing individual solder joints. Specialized equipment and skilled technicians are required to perform BGA Rework and repair effectively.

Frequently Asked Questions (FAQ)

- What is BGA in PCB assembly?

-

BGA stands for Ball Grid Array, a surface-mount packaging technology that uses an array of solder balls to connect the integrated circuit (IC) to the PCB.

-

What are the advantages of using BGA packages in PCB assembly?

-

BGA packages offer several advantages, including increased packaging density, improved electrical performance, better thermal dissipation, and reduced lead inductance.

-

How do I choose the right BGA PCB assembly company for my project?

-

When choosing a BGA PCB assembly company, consider factors such as technical capabilities, industry experience, scalability, design and engineering support, supply chain management, and communication and collaboration.

-

What are the key steps in the BGA PCB assembly process?

-

The key steps in the BGA PCB assembly process include solder paste printing, component placement, reflow soldering, inspection, and testing.

-

What are some of the challenges in BGA PCB assembly, and how can they be addressed?

- Challenges in BGA PCB assembly include thermal management, warpage and coplanarity, solder joint reliability, and rework and repair. These challenges can be addressed through proper PCB design, component selection, process control, and the use of specialized equipment and skilled technicians.

Conclusion

BGA PCB assembly is a critical process in the production of modern electronic devices, offering numerous advantages over traditional packaging methods. Choosing the right BGA PCB assembly company is essential for ensuring the quality, reliability, and success of your project. By considering factors such as technical capabilities, industry experience, and scalability, and by understanding the challenges and best practices in BGA PCB assembly, you can select a partner that will help you bring your electronic product to market efficiently and effectively.

Leave a Reply