PCB Blog

-

Read more: What’s the difference between Rigid PCB and Flexible PCB?

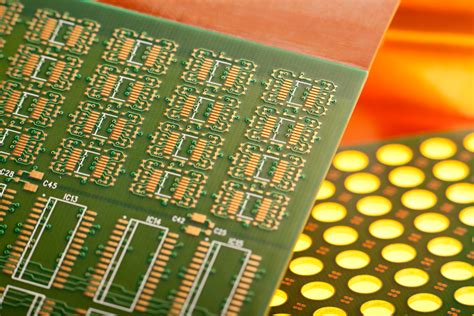

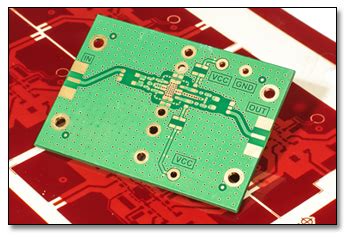

Read more: What’s the difference between Rigid PCB and Flexible PCB?What is a Rigid PCB? A rigid PCB is a printed circuit board that is made from a solid, non-flexible substrate material, typically FR-4 glass epoxy. The board is composed of multiple layers of copper foil laminated together with the substrate, forming a rigid and sturdy structure. Rigid PCBs are […]

-

Read more: Things to consider while you look for fast PCB prototype in the USA!

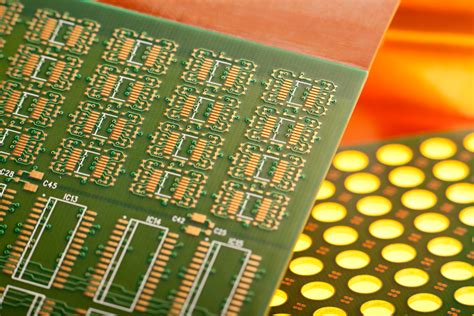

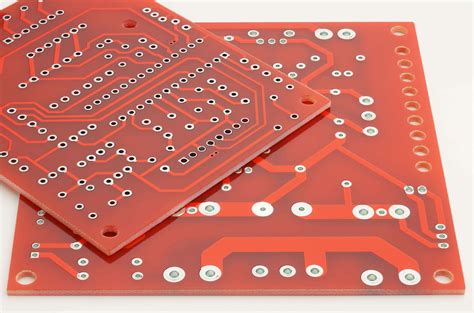

Read more: Things to consider while you look for fast PCB prototype in the USA!Understanding PCB Prototyping What is a PCB Prototype? A PCB prototype is a physical representation of your electronic circuit design. It is a fully functional, one-off version of your PCB that allows you to test and refine your design before committing to large-scale production. PCB prototypes are essential for identifying […]

-

What is PCB Prototype sernice?

Posted by

–

Read more: What is PCB Prototype sernice?

Read more: What is PCB Prototype sernice?The Importance of PCB Prototyping PCB prototyping is a critical phase in the product development lifecycle. It allows designers and engineers to: Test and validate the design Identify and fix any issues or errors Optimize the design for manufacturability and cost-effectiveness Ensure the product meets the required specifications and standards […]

-

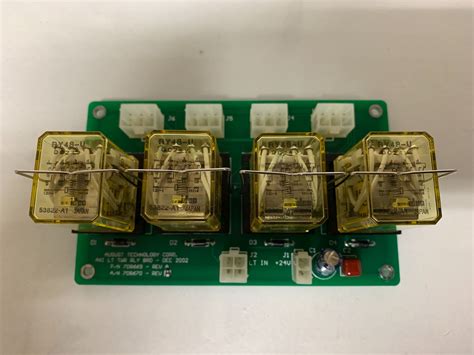

Read more: Why and when you need to outsource electromechanical assemblies?

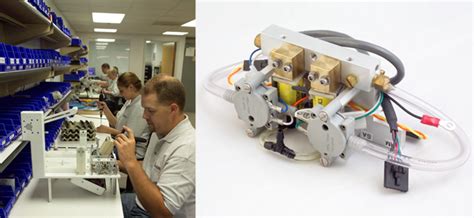

Read more: Why and when you need to outsource electromechanical assemblies?Introduction to Electromechanical Assemblies and Outsourcing Electromechanical assemblies are a crucial component in various industries, including aerospace, automotive, medical devices, and consumer electronics. These assemblies combine electrical and mechanical components to create complex systems that perform specific functions. As technology advances and market demands evolve, companies face the challenge of […]

-

Read more: Why Ball Grid Array (BGA) is important in PCB assembly?

Read more: Why Ball Grid Array (BGA) is important in PCB assembly?What is Ball Grid Array (BGA)? Ball Grid Array (BGA) is a surface-mount packaging technology used for integrated circuits (ICs) and other electronic components. It consists of a grid of solder balls on the bottom side of the package, which are used to connect the component to the PCB. The […]

-

Read more: Why Bill of Materials (BOM) is important in PCB Manufacturing process?

Read more: Why Bill of Materials (BOM) is important in PCB Manufacturing process?Introduction to BOM and Its Significance in PCB Manufacturing A Bill of Materials (BOM) is a comprehensive list of all the components, parts, and materials required to manufacture a product. In the context of Printed Circuit Board (PCB) manufacturing, a BOM plays a crucial role in ensuring the accuracy, efficiency, […]

-

Read more: Why choose Automated X-Ray Inspection (AXI) Technology in PCB Assembly?

Read more: Why choose Automated X-Ray Inspection (AXI) Technology in PCB Assembly?What is AXI Technology? Automated X-Ray Inspection (AXI) is a non-destructive testing method that uses X-rays to inspect the internal structure of PCBs. This technology allows for the detection of defects that are not visible to the naked eye or other optical inspection methods. AXI systems use high-resolution X-ray imaging […]

-

Read more: PCB Assembly Companies with Automated X-Ray Inspection (AXI)

Read more: PCB Assembly Companies with Automated X-Ray Inspection (AXI)What is Automated X-Ray Inspection (AXI)? Automated X-Ray Inspection (AXI) is a sophisticated quality control method used in the PCB Assembly process. It utilizes X-ray imaging to create detailed images of the internal structures of PCBs, allowing for the detection of defects that may not be visible to the naked […]

-

Read more: What is the difference between full spec standard PCB production and PCB prototyping?

Read more: What is the difference between full spec standard PCB production and PCB prototyping?Introduction to PCB Prototyping PCB prototyping is the process of creating a preliminary version of a printed circuit board (PCB) for testing and evaluation purposes before going into full-scale production. It allows designers and engineers to validate their designs, check for any errors or issues, and make necessary modifications before […]

-

Read more: Why Additive Manufacturing is the Right for your PCB Electronics Assembly?

Read more: Why Additive Manufacturing is the Right for your PCB Electronics Assembly?Introduction to PCB Additive Manufacturing Printed Circuit Board (PCB) manufacturing has come a long way since its inception. Traditional PCB manufacturing methods, such as subtractive manufacturing, have been the go-to choice for electronics assembly for decades. However, with the advent of additive manufacturing technologies, the landscape of PCB production is […]

Recent Posts

- Best Practices to Ensure the Correct Component Orientation by Optimized assembly PCB board!

- Build a New Product quickly with PCB Assembly Prototyping – A Brief Guide!

- Can you provide complete PCB box-build services?

- Tips for Choosing the Perfect Cable Assembly Manufacturer!

- Top 10 Best PCB routing practices!

Categories

- PCB Blog 835