PCB Blog

-

Through hole pin length and PCB thickness

Posted by

–

Read more: Through hole pin length and PCB thickness

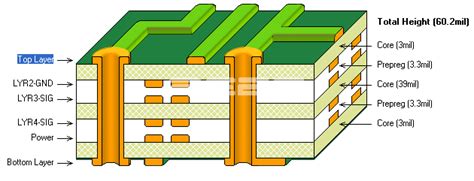

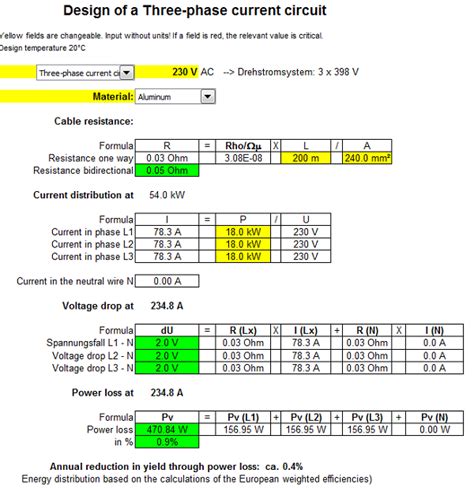

Read more: Through hole pin length and PCB thicknessIntroduction to PCB Thickness and Pin Length In the world of printed circuit board (PCB) design, the thickness of the board and the length of the through hole pins are critical factors that determine the functionality, durability, and overall performance of the electronic device. The relationship between PCB thickness and […]

-

Reverse generated PCB GERBER files

Posted by

–

Read more: Reverse generated PCB GERBER files

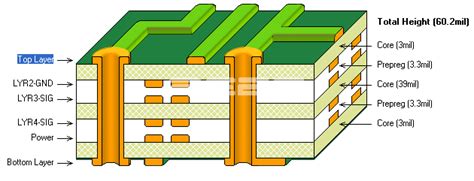

Read more: Reverse generated PCB GERBER filesIntroduction to PCB GERBER Files PCB GERBER files are the standard file format used in the PCB industry for manufacturing printed circuit boards. These files contain all the necessary information required to fabricate a PCB, including the copper layers, solder mask, silkscreen, and drill data. GERBER files are named after […]

-

What Is The PCB Current Calculator(Latest)

Posted by

–

Read more: What Is The PCB Current Calculator(Latest)

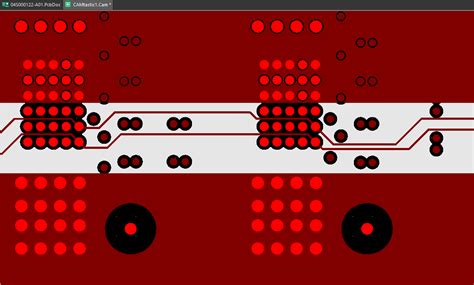

Read more: What Is The PCB Current Calculator(Latest)Introduction to PCB Current Calculators A printed circuit board (PCB) current calculator is an essential tool for electrical engineers and PCB designers. It allows you to accurately determine the maximum current carrying capacity of the traces on a PCB based on various factors such as trace width, thickness, temperature rise, […]

-

How to define these board edge holes

Posted by

–

Read more: How to define these board edge holes

Read more: How to define these board edge holesWhat are Board Edge Holes? Board edge holes, also known as edge-plated holes or Castellated Holes, are a type of mechanical feature found on printed circuit boards (PCBs). These holes are located along the edges of the PCB and are used for various purposes, such as: Allowing the PCB to […]

-

Read more: The Ultimate Guide to PCB Solderability Test and Functionality

Read more: The Ultimate Guide to PCB Solderability Test and FunctionalityIntroduction to PCB Solderability Printed Circuit Board (PCB) solderability is a critical factor in ensuring the reliability and functionality of electronic devices. Solderability refers to the ability of a surface to be wetted by molten solder and form a strong mechanical and electrical bond. In the manufacturing process of PCBs, […]

-

Read more: Castellated PCB: An Excellent Way to Assemble Boards

Read more: Castellated PCB: An Excellent Way to Assemble BoardsIntroduction to Castellated PCB Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. They provide a platform for mounting and connecting various electronic components to create a functional circuit. One of the most popular methods of assembling PCBs is through the use of Castellated Holes. Castellated PCBs offer […]

-

PCB Manufacturer China vs US

Posted by

–

Read more: PCB Manufacturer China vs US

Read more: PCB Manufacturer China vs USIntroduction to PCB Manufacturing Printed Circuit Boards (PCBs) are the backbone of modern electronics, forming the foundation for countless devices that we rely on in our daily lives. From smartphones and laptops to medical equipment and aerospace systems, PCBs play a crucial role in enabling the functionality and performance of […]

-

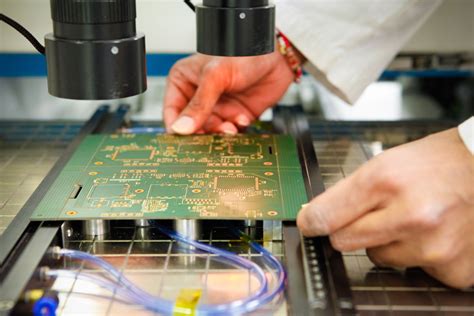

PCB Manufacturing Service

Posted by

–

Read more: PCB Manufacturing Service

Read more: PCB Manufacturing ServiceIntroduction to PCB Manufacturing Printed Circuit Board (PCB) manufacturing is a critical process in the electronics industry, enabling the creation of complex circuitry on a compact and durable substrate. PCBs are found in nearly all electronic devices, from smartphones and computers to industrial equipment and medical devices. This article will […]

-

PCB Via Types

Posted by

–

Read more: PCB Via Types

Read more: PCB Via TypesWhat are PCB Vias? PCB vias are small holes drilled through a printed circuit board that allow electrical signals to pass from one layer of the board to another. Vias are an essential component in multi-layer PCBs, enabling more complex and compact designs by allowing traces to cross over each […]

-

Mixed Assembly Advantages

Posted by

–

Read more: Mixed Assembly Advantages

Read more: Mixed Assembly AdvantagesWhat is Mixed Assembly? Mixed assembly is a manufacturing technique that combines both automated and manual assembly processes to create a final product. This approach leverages the strengths of both human workers and machines to achieve optimal efficiency, quality, and flexibility in the production process. In a mixed assembly system, […]

Recent Posts

- Best Practices to Ensure the Correct Component Orientation by Optimized assembly PCB board!

- Build a New Product quickly with PCB Assembly Prototyping – A Brief Guide!

- Can you provide complete PCB box-build services?

- Tips for Choosing the Perfect Cable Assembly Manufacturer!

- Top 10 Best PCB routing practices!

Categories

- PCB Blog 835