PCB Blog

-

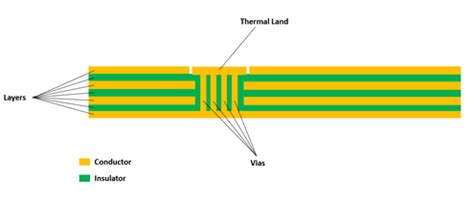

PCB Thermal Conductivity and Its Importance

Posted by

–

Read more: PCB Thermal Conductivity and Its Importance

Read more: PCB Thermal Conductivity and Its ImportanceWhat is PCB thermal conductivity? PCB (Printed Circuit Board) thermal conductivity refers to the ability of a PCB material to conduct heat. It is a crucial property that determines how effectively heat can be transferred from the components on the PCB to the surrounding environment. Thermal conductivity is measured in […]

-

Read more: Rayming and CadSoft EAGLE match your needs for electronics development

Read more: Rayming and CadSoft EAGLE match your needs for electronics developmentIntroduction to Rayming and CadSoft EAGLE RAYMING PCB & Assembly is a leading provider of printed circuit board (PCB) design, fabrication, and assembly services. They have partnered with CadSoft Computer to offer the EAGLE PCB design software to help engineers and hobbyists bring their electronic designs to life. EAGLE (Easily […]

-

Guide to the Rayming PCB Calculator – calculate prices, get quotations, analyse your data

Posted by

–

Read more: Guide to the Rayming PCB Calculator – calculate prices, get quotations, analyse your data

Read more: Guide to the Rayming PCB Calculator – calculate prices, get quotations, analyse your dataIntroduction to the Rayming PCB Calculator The RAYMING PCB Calculator is a powerful tool designed to help engineers, designers, and manufacturers streamline the process of calculating prices, obtaining quotations, and analyzing data for printed circuit board (PCB) projects. This comprehensive guide will walk you through the features and benefits of […]

-

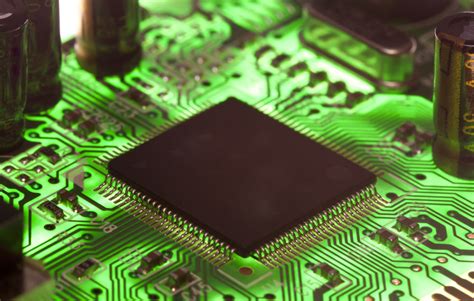

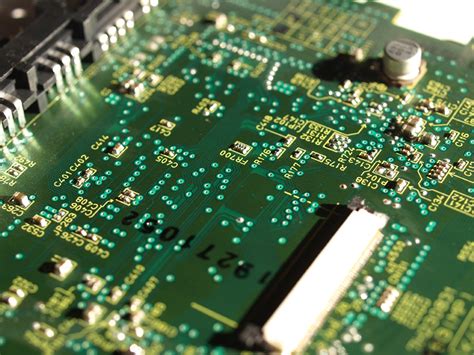

PCBA Manufacturing: A Step-by-Step Guide

Posted by

–

Read more: PCBA Manufacturing: A Step-by-Step Guide

Read more: PCBA Manufacturing: A Step-by-Step GuideWhat is PCBA Manufacturing? PCBA manufacturing is the process of assembling various electronic components onto a printed circuit board (PCB) to create a functional electronic device. The process involves several steps, including PCB design, component selection, solder paste application, component placement, reflow soldering, inspection, and testing. Request Ceramic PCB Manufacturing […]

-

Professional LED PCB Assembly Supplier

Posted by

–

Read more: Professional LED PCB Assembly Supplier

Read more: Professional LED PCB Assembly SupplierIntroduction to LED PCB Assembly Light-emitting diode (LED) printed circuit board (PCB) assembly is a crucial process in the manufacturing of LED lighting products. LED PCBs are designed to provide electrical connections and mechanical support for LED components, ensuring optimal performance and reliability. As the demand for energy-efficient and long-lasting […]

-

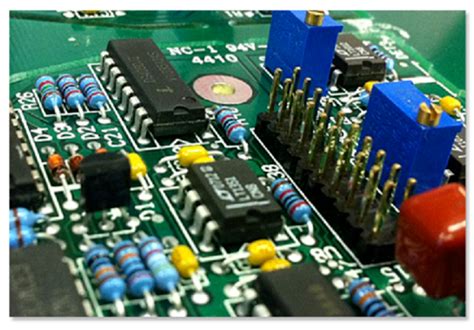

RAYMING Is A Through Hole PCB Assembly Expert

Posted by

–

Read more: RAYMING Is A Through Hole PCB Assembly Expert

Read more: RAYMING Is A Through Hole PCB Assembly ExpertIntroduction to RAYMING and Through-hole PCB Assembly RAYMING is a leading provider of through-hole PCB Assembly services, with years of experience and expertise in the industry. Through-hole PCB assembly is a process of mounting electronic components onto a printed circuit board (PCB) by inserting their leads through holes drilled in […]

-

Read more: RAYMING: Your First Choice of Quick Turn PCB Manufacturing

Read more: RAYMING: Your First Choice of Quick Turn PCB ManufacturingIntroduction to RAYMING PCB RAYMING PCB is a leading provider of quick turn printed circuit board (PCB) manufacturing services. With state-of-the-art facilities and a team of experienced professionals, RAYMING PCB offers high-quality PCBs with fast turnaround times to meet the demands of today’s rapidly evolving electronics industry. What is Quick […]

-

Reflow soldering on PCB

Posted by

–

Read more: Reflow soldering on PCB

Read more: Reflow soldering on PCBIntroduction to Reflow soldering Reflow soldering is a process used in the manufacturing of printed circuit boards (PCBs) to attach surface-mount components to the board. This technique involves applying solder paste to the PCB, placing the components, and then heating the entire assembly to melt the solder and create a […]

-

Where to get a fastest PCB Assembly prototype

Posted by

–

Read more: Where to get a fastest PCB Assembly prototype

Read more: Where to get a fastest PCB Assembly prototypeIntroduction to PCB Assembly PCB assembly is the process of attaching electronic components to a printed circuit board (PCB) to create a functional electronic device. The process involves several steps, including placing components on the board, soldering them in place, and testing the completed assembly to ensure it functions as […]

-

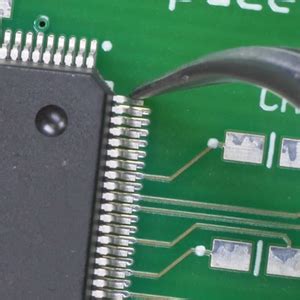

How to solve the problem of QFP solder bridging

Posted by

–

Read more: How to solve the problem of QFP solder bridging

Read more: How to solve the problem of QFP solder bridgingWhat is QFP Solder Bridging? QFP (Quad Flat Package) solder bridging is a common defect that occurs when soldering QFP Integrated Circuits to printed circuit boards (PCBs). QFP packages have leads on all four sides of the IC chip. The leads are spaced very close together, typically with a pitch […]

Recent Posts

- Best Practices to Ensure the Correct Component Orientation by Optimized assembly PCB board!

- Build a New Product quickly with PCB Assembly Prototyping – A Brief Guide!

- Can you provide complete PCB box-build services?

- Tips for Choosing the Perfect Cable Assembly Manufacturer!

- Top 10 Best PCB routing practices!

Categories

- PCB Blog 835