Introduction to PCB assembly

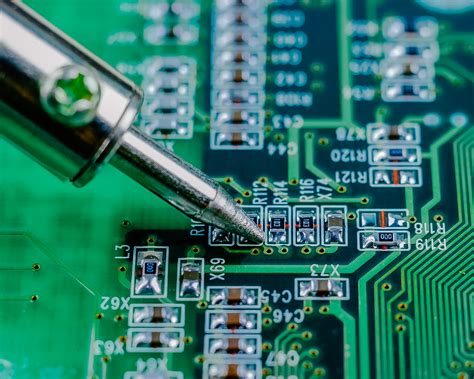

Printed Circuit Board (PCB) assembly is a crucial process in the manufacturing of electronic devices. It involves the mounting of electronic components onto a printed circuit board to create a functional circuit. PCB assembly is a complex process that requires precision, accuracy, and attention to detail. In this article, we will explore the industrial process of PCB assembly by RAYPCB, a leading manufacturer of high-quality PCBs.

The PCB Assembly Process

The PCB assembly process consists of several steps, each of which is critical to the success of the final product. The steps involved in PCB assembly include:

- Solder Paste Printing

- Component Placement

- Reflow soldering

- Inspection and Testing

- Final Assembly and Packaging

Let’s take a closer look at each step in the PCB assembly process.

Step 1: Solder Paste Printing

The first step in the PCB assembly process is solder paste printing. Solder paste is a mixture of tiny Solder Balls and flux that is applied to the PCB using a stencil. The stencil is a thin metal sheet with holes that correspond to the pads on the PCB. The solder paste is applied to the stencil using a squeegee, which forces the paste through the holes and onto the PCB.

| Solder Paste Property | Description |

|---|---|

| Composition | Mixture of tiny solder balls and flux |

| Application Method | Applied to PCB using a stencil and squeegee |

| Purpose | To provide electrical and mechanical connection between components and PCB |

Step 2: Component Placement

Once the solder paste has been applied to the PCB, the next step is component placement. This is done using a pick-and-place machine, which uses a vacuum nozzle to pick up the components and place them onto the PCB. The machine is programmed with the specific location and orientation of each component on the PCB.

| Component Placement Machine Property | Description |

|---|---|

| Type | Pick-and-place machine |

| Functionality | Uses vacuum nozzle to pick up and place components onto PCB |

| Programming | Programmed with specific location and orientation of each component on PCB |

Step 3: Reflow Soldering

After the components have been placed onto the PCB, the next step is reflow soldering. This is done by passing the PCB through a reflow oven, which heats the solder paste to a specific temperature profile. The heat causes the solder paste to melt and form a permanent bond between the components and the PCB.

| Reflow Soldering Process Property | Description |

|---|---|

| Equipment | Reflow oven |

| Purpose | To melt solder paste and form permanent bond between components and PCB |

| Temperature Profile | Specific temperature profile used to melt solder paste effectively |

Step 4: Inspection and Testing

Once the PCB has been soldered, it undergoes a series of inspections and tests to ensure that it meets the required specifications. This includes visual inspection, automated optical inspection (AOI), and functional testing.

| Inspection and Testing Method | Description |

|---|---|

| Visual Inspection | Manual inspection of PCB for defects and irregularities |

| Automated Optical Inspection (AOI) | Automated Inspection using cameras and image processing software to detect defects |

| Functional Testing | Testing of PCB functionality to ensure it meets required specifications |

Step 5: Final Assembly and Packaging

The final step in the PCB assembly process is final assembly and packaging. This involves attaching any additional components or hardware to the PCB, such as connectors or heat sinks. The PCB is then packaged and shipped to the customer.

Advantages of PCB Assembly by RAYPCB

RAYPCB is a leading manufacturer of high-quality PCBs, with a focus on providing exceptional service and support to its customers. Some of the advantages of PCB assembly by RAYPCB include:

- State-of-the-art equipment and technology

- Experienced and skilled technicians

- Strict quality control measures

- Fast turnaround times

- Competitive pricing

Frequently Asked Questions (FAQ)

1. What is the typical turnaround time for PCB assembly by RAYPCB?

The typical turnaround time for PCB assembly by RAYPCB varies depending on the complexity of the project and the quantity of PCBs required. However, RAYPCB strives to provide fast turnaround times while maintaining the highest level of quality. For standard projects, the turnaround time is typically 7-10 days.

2. What types of PCBs can RAYPCB assemble?

RAYPCB can assemble a wide range of PCBs, including single-sided, double-sided, and multi-layer PCBs. They can also assemble PCBs with various surface finishes, such as HASL, lead-free HASL, immersion gold, and OSP.

3. What is the minimum order quantity for PCB assembly by RAYPCB?

The minimum order quantity for PCB assembly by RAYPCB varies depending on the complexity of the project and the specific requirements of the customer. However, RAYPCB is able to accommodate small batch orders as well as large volume production runs.

4. What quality control measures does RAYPCB have in place?

RAYPCB has strict quality control measures in place to ensure that every PCB meets the highest standards of quality. This includes visual inspection, automated optical inspection (AOI), and functional testing. RAYPCB also has a dedicated quality control team that monitors the entire PCB assembly process to ensure that every PCB meets the required specifications.

5. How does RAYPCB Ensure the security and confidentiality of customer data?

RAYPCB takes the security and confidentiality of customer data very seriously. They have strict security measures in place to protect customer data, including secure servers, encrypted communication, and restricted access to sensitive information. RAYPCB also has a strict confidentiality agreement in place with all employees to ensure that customer data is protected at all times.

Conclusion

PCB assembly is a complex process that requires precision, accuracy, and attention to detail. RAYPCB is a leading manufacturer of high-quality PCBs, with a focus on providing exceptional service and support to its customers. By using state-of-the-art equipment and technology, experienced and skilled technicians, and strict quality control measures, RAYPCB is able to provide high-quality PCB assembly services with fast turnaround times and competitive pricing. If you’re looking for a reliable and trusted partner for your PCB assembly needs, look no further than RAYPCB.

Leave a Reply