Understanding PCB Prototypes

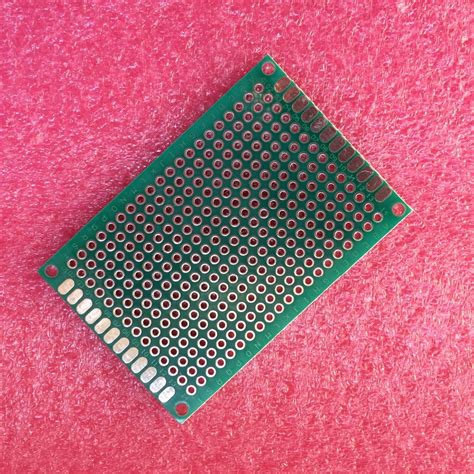

Before we dive into the details of choosing a manufacturer, let’s first define what a PCB prototype is and why it’s important.

What is a PCB Prototype?

A PCB prototype is an initial version of a printed circuit board that is used for testing and validation purposes. It allows designers and engineers to assess the functionality, performance, and compatibility of their circuit design before moving into mass production. PCB Prototypes are typically produced in small quantities and may undergo several iterations based on the results of testing and feedback.

The Importance of PCB Prototypes

Creating a PCB prototype offers several benefits:

-

Design Validation: PCB prototypes allow you to physically test your circuit design and ensure that it functions as intended. This helps identify any design flaws or issues early in the development process.

-

Compatibility Testing: By assembling a PCB prototype, you can verify the compatibility of your design with other components and systems. This is particularly important when integrating your PCB with existing hardware or software.

-

Cost Savings: Identifying and resolving issues during the prototyping phase can save significant costs compared to discovering problems during mass production. PCB prototypes help minimize the risk of expensive redesigns and manufacturing errors.

-

Proof of Concept: PCB prototypes serve as a tangible demonstration of your design’s viability. They can be used to showcase your product to stakeholders, investors, or potential customers.

Now that we understand the significance of PCB prototypes, let’s explore the factors to consider when choosing a manufacturer.

Factors to Consider When Choosing a PCB Prototype Manufacturer

1. Manufacturing Capabilities

One of the primary factors to consider when selecting a PCB prototype manufacturer is their manufacturing capabilities. Here are some key aspects to evaluate:

PCB Layers

PCBs can have varying numbers of layers, ranging from single-sided to multi-layered boards. Ensure that the manufacturer you choose has the capability to produce the number of layers required for your design. Some manufacturers specialize in specific layer counts, while others offer a wide range of options.

PCB Materials

Different PCB materials have distinct properties and are suited for specific applications. Common PCB materials include FR-4, high-frequency laminates, and flexible substrates. Verify that the manufacturer has experience working with the materials required for your project and can provide the necessary expertise and guidance.

Minimum Feature Size

The minimum feature size refers to the smallest trace width and spacing that a manufacturer can reliably produce. If your design includes fine-pitch components or high-density layouts, ensure that the manufacturer can accommodate your requirements. Choosing a manufacturer with advanced capabilities in terms of minimum feature size can help you achieve more compact and efficient PCB designs.

Surface Finishes

PCBs can have various surface finishes that provide protection and enhance solderability. Common surface finishes include Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), and Immersion Silver (IAg). Discuss your specific requirements with the manufacturer and ensure they offer the surface finish options that meet your needs.

2. Quality Control and Certifications

When it comes to PCB prototypes, quality is paramount. A reliable manufacturer should have robust quality control processes in place to ensure the consistency and reliability of their products. Here are some quality-related factors to consider:

ISO Certification

ISO (International Organization for Standardization) certifications demonstrate a manufacturer’s commitment to quality management and standardized processes. Look for manufacturers with relevant ISO certifications, such as ISO 9001 for quality management systems or ISO 14001 for environmental management systems.

IPC Standards

IPC (Association Connecting Electronics Industries) is a global trade association that sets standards for the electronics industry. Ensure that the manufacturer adheres to relevant IPC standards, such as IPC-A-600 for acceptability of printed boards or IPC-6012 for qualification and performance specifications for rigid printed boards. Compliance with IPC standards indicates that the manufacturer follows industry-recognized guidelines and best practices.

Testing and Inspection

Inquire about the manufacturer’s testing and inspection procedures. A reputable manufacturer should have a comprehensive quality control process that includes visual inspection, electrical testing, and functionality testing. Ask about their testing equipment, such as automated optical inspection (AOI) machines or flying probe testers, to ensure they have the necessary tools to detect and address any defects or issues.

3. Turnaround Time and Pricing

When developing a PCB prototype, time is often of the essence. You want to receive your prototype quickly to validate your design and move forward with your project. Additionally, cost is a significant consideration, especially for low-cost PCB prototypes. Consider the following factors related to turnaround time and pricing:

Standard and Expedited Turnaround Options

Manufacturers typically offer standard and expedited turnaround options for PCB prototypes. Standard turnaround times can range from several days to a couple of weeks, while expedited options may provide faster delivery at an additional cost. Evaluate your project timeline and budget to determine the most suitable turnaround option for your needs.

Minimum Order Quantity (MOQ)

Some manufacturers have minimum order quantity (MOQ) requirements for PCB prototypes. This means you may need to order a certain number of boards, even if you only need a few for testing. Look for manufacturers with low or no MOQ requirements to avoid unnecessary costs and excess inventory.

Pricing and Volume Discounts

Compare pricing from multiple manufacturers to ensure you’re getting a competitive rate for your PCB prototype. Keep in mind that the lowest price may not always equate to the best value. Consider factors such as quality, reliability, and customer support when making your decision. Additionally, inquire about volume discounts if you anticipate ordering larger quantities of prototypes in the future.

4. Design Support and Communication

Effective communication and design support are crucial when working with a PCB prototype manufacturer. Look for a manufacturer that offers the following:

Design Review and Feedback

A reputable manufacturer should provide design review services to ensure your PCB layout is optimized for manufacturing. They can offer feedback on design rules, component placement, and potential issues that may affect the manufacturability of your board. This valuable input can help you refine your design and avoid costly mistakes.

File Format Compatibility

Verify that the manufacturer accepts the PCB design file formats you work with, such as Gerber files, ODB++, or Eagle files. Ensure that they have the necessary software and expertise to handle your specific design files without any compatibility issues.

Responsive Communication

Choose a manufacturer with responsive and clear communication channels. They should be readily available to answer your questions, provide updates on your project status, and address any concerns you may have. Good communication helps build trust and ensures a smooth collaboration throughout the prototyping process.

5. Customer Support and Reputation

Finally, consider the level of customer support and the reputation of the PCB prototype manufacturer. Here are some aspects to evaluate:

Technical Support

Look for a manufacturer that offers reliable technical support. They should have knowledgeable staff who can assist you with any technical questions or issues you may encounter during the prototyping process. Responsive and helpful technical support can save you time and frustration, especially if you’re new to PCB design or encounter unexpected challenges.

Customer Reviews and Testimonials

Research the manufacturer’s reputation by reading customer reviews and testimonials. Look for feedback from other designers or engineers who have worked with the manufacturer. Positive reviews and testimonials can provide valuable insights into the manufacturer’s quality, reliability, and customer service.

Industry Experience and Expertise

Consider the manufacturer’s experience and expertise in the PCB industry. A manufacturer with a long-standing history and a diverse portfolio of successful projects can indicate their reliability and capability to handle your specific requirements. Look for manufacturers who have experience in your particular industry or application area, as they may have valuable insights and best practices to share.

PCB Prototype Manufacturer Comparison

To help you make an informed decision, we’ve compiled a comparison table of popular PCB prototype manufacturers:

| Manufacturer | Layers | Materials | Min. Feature Size | Turnaround Time | MOQ |

|---|---|---|---|---|---|

| PCBWay | 1-16 | FR-4, Aluminum, Flexible | 3 mil (0.075 mm) | 24 hours (expedited), 3-5 days (standard) | 5 |

| JLCPCB | 1-6 | FR-4 | 3.5 mil (0.089 mm) | 24 hours (expedited), 3-5 days (standard) | 5 |

| OSH Park | 1-4 | FR-4 | 6 mil (0.152 mm) | 5-12 days (standard) | 3 |

| Seeed Studio | 1-16 | FR-4, Aluminum, Flexible | 3 mil (0.075 mm) | 3-5 days (standard) | 5 |

Note: The information provided in the table is based on the manufacturers’ specifications and may be subject to change. Always verify the latest information directly with the manufacturer.

Frequently Asked Questions (FAQs)

-

What is the typical cost of a low-cost PCB prototype?

The cost of a low-cost PCB prototype can vary depending on factors such as the PCB size, number of layers, materials, and quantity. On average, you can expect to pay around $10 to $50 for a small batch of low-cost PCB prototypes. -

How long does it usually take to receive a PCB prototype?

The turnaround time for PCB prototypes depends on the manufacturer and the selected service option. Standard turnaround times range from a few days to a couple of weeks, while expedited options can deliver prototypes within 24 to 48 hours. -

Can I get a single PCB prototype, or is there a minimum order quantity?

Some manufacturers have minimum order quantity (MOQ) requirements for PCB prototypes, typically ranging from 3 to 10 pieces. However, there are manufacturers who offer services with no MOQ, allowing you to order a single prototype if needed. -

What files do I need to provide to the manufacturer for PCB prototyping?

To fabricate your PCB prototype, you’ll typically need to provide Gerber files, which are industry-standard files that contain the necessary information for manufacturing. Additionally, you may need to provide drill files, solder mask files, and silkscreen files, depending on your design requirements. -

Can I request a specific surface finish for my PCB prototype?

Yes, most PCB prototype manufacturers offer a range of surface finish options, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). You can specify your preferred surface finish when placing your order.

Conclusion

Choosing the perfect manufacturer for your low-cost PCB prototype requires careful consideration of various factors. By evaluating a manufacturer’s capabilities, quality control measures, turnaround time, pricing, design support, and customer service, you can make an informed decision that aligns with your project requirements and budget.

Remember, a well-manufactured PCB prototype is crucial for validating your design, identifying potential issues, and ensuring the success of your final product. Take the time to research and compare different manufacturers to find the one that best suits your needs.

With the right PCB prototype manufacturer as your partner, you can bring your electronic designs to life with confidence and efficiency. Happy prototyping!

Leave a Reply